Forest Transport System

Designing an efficient cargo transport solution for forest environments presented unique challenges: navigating narrow trails, maintaining stability on uneven terrain, and providing sufficient payload capacity while remaining lightweight and maneuverable.

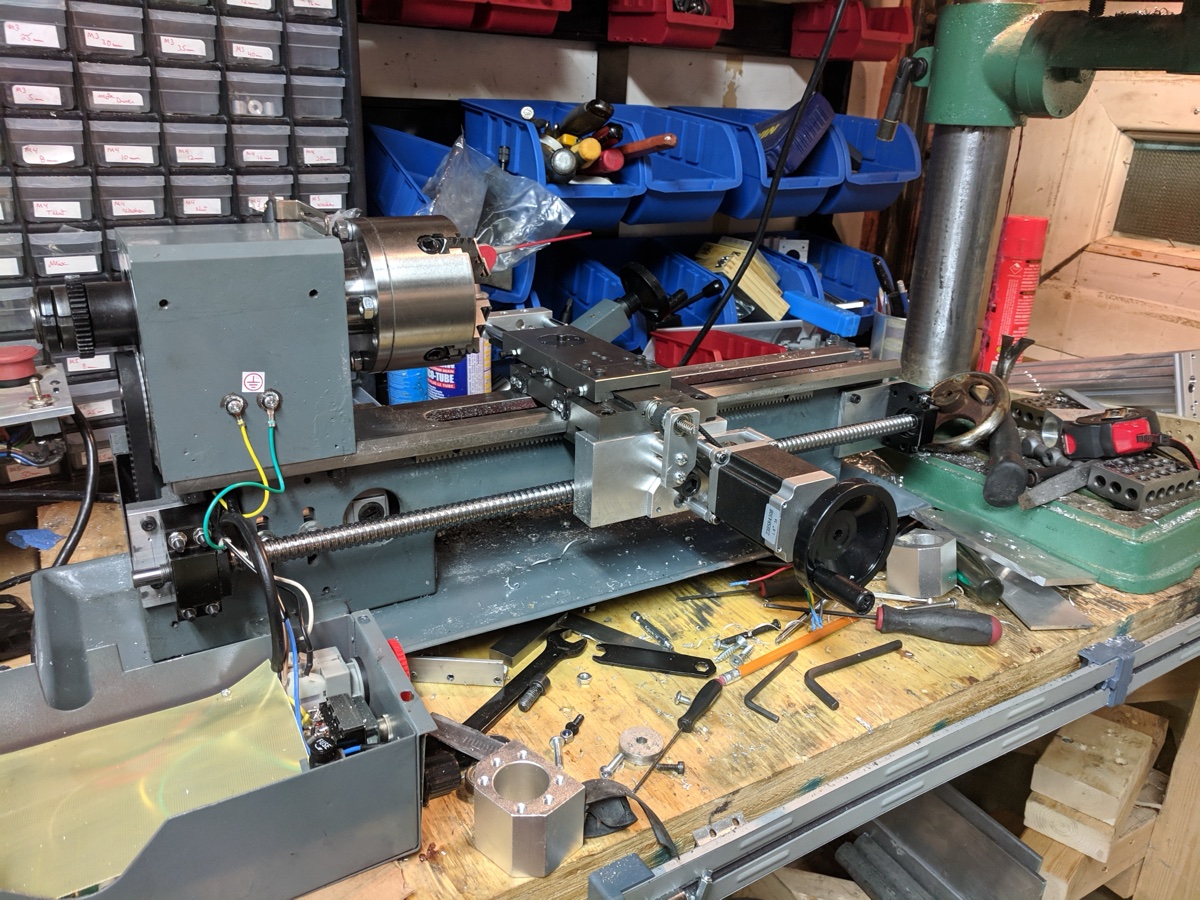

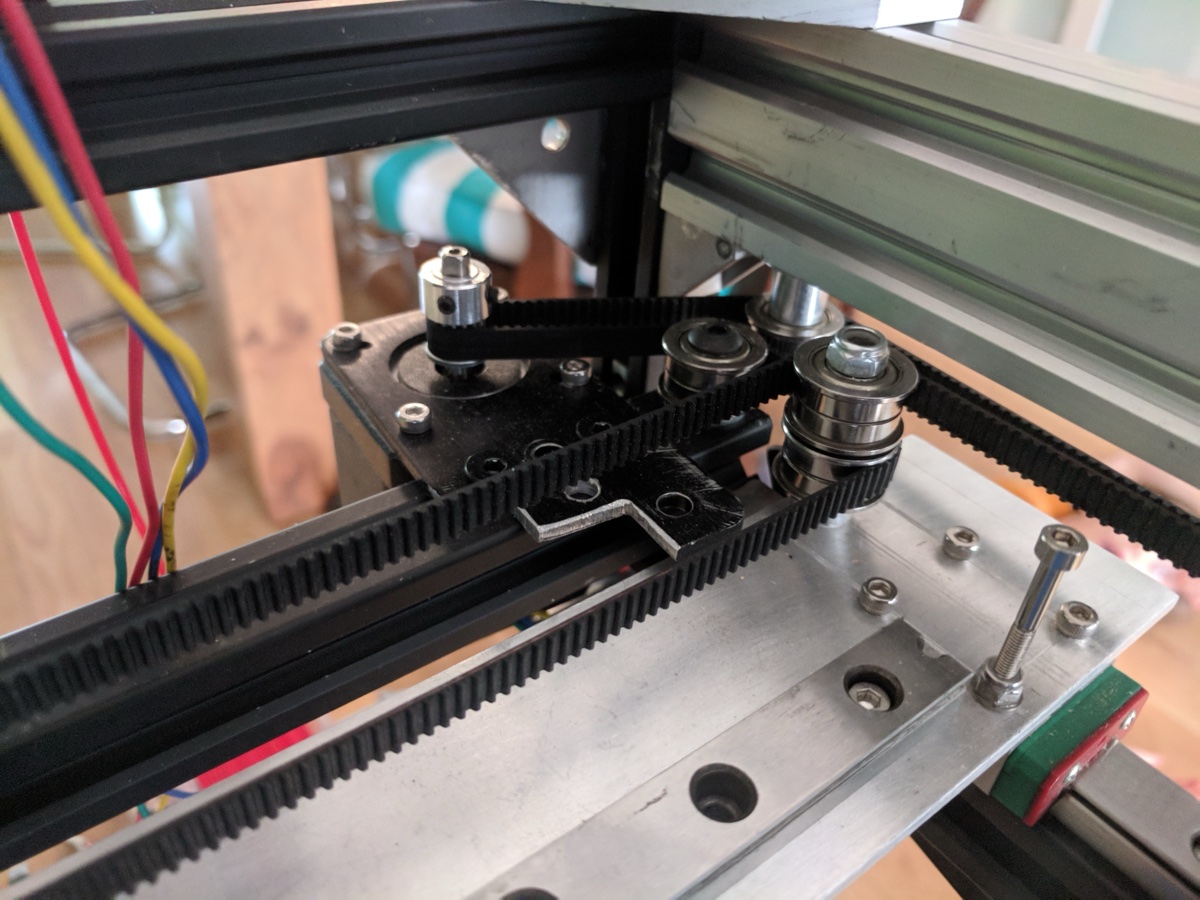

The single-track design emerged from analyzing trail constraints and load distribution requirements. The plywood chassis balances structural integrity with weight optimization, while the electric drive system provides precise speed control essential for safe forest navigation. The rear-trailing wheel configuration allows tight turns while maintaining tracking stability.

Through iterative testing in various terrain conditions, the system demonstrates reliable performance across steep grades, loose surfaces, and obstacle-rich environments. The modular design enables quick reconfiguration for different cargo types and operational requirements.